The evolution of bows

Bow Basics

What is a bow? The Cambridge (because that is where we are based) dictionary lists the definition as “A weapon for shooting arrows, made of a long thin piece of wood or fibreglass bent into a curve by a tightly stretched string”. So, regardless of the bow type they are all essentially doing the same job – acting as a spring and transferring kinetic energy from the bow, via the string, to the arrow in order to propel it forward.

The Self Bow (long bow)

As discussed in my previous article about the history of archery, the self-bow now has an incredibly well-preserved example, that of Ötzi the ice man whose remains were stumbled across by a German couple during a summer hike in 1991 in the Ötztal Alps in southern Tyrol. Among the many items that were discovered with the man’s mummified remains was a bow and a quiver of arrows. All Longbows are self-bows – including the one found with Ötzi. They are made from a single piece of wood using the properties of the sap and heart woods to generate.

Sapwood is the part of the tree that carries nutrients from one part of the tree to another. It surrounds the heartwood which is dead and has darkened due to toxins in the core. Heartwood imparts strength and rigidity to the tree, and when buffeted by the wind it compresses, the surrounding sapwood’s flexibility absorbs the tension and helps prevent the tree from breaking. The strongest self-bows are constructed using the bole (trunk) of the tree rather than the limbs as that is where the strongest staves can be harvested. Although self-bows can be made from different woods, notably yew, ash, or elm, it is yew that truly excels.

A self-bow is constructed with the heartwood forming the belly and sapwood is the back of the bow. When the bow is drawn back the heartwood is forced into compression and energy potential builds up in the limbs. The stretched sapwood takes on the tension and prevents the bow from snapping, just as it did when the stave was a part of the tree.

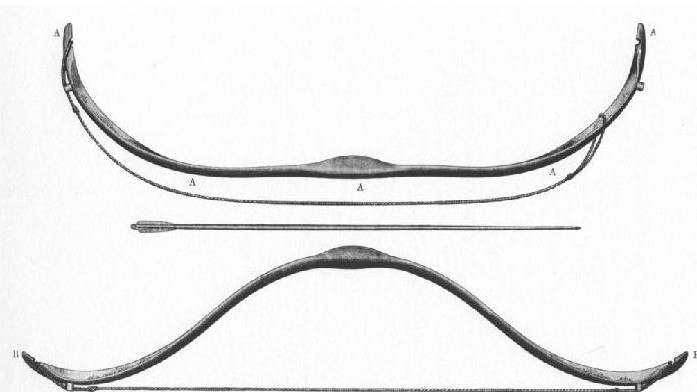

The Composite Bow

History shows us that composite bows have been built and used in an incredible variety of shapes and sizes. But they all have one thing in common – rather than being made from a single stave of wood (self-bows) they were composed of three or more layers of dissimilar materials, as a clever combination of natural materials with different properties offers many advantages for designing efficient bows.

All bows are essentially a simple form of spring. When the string is pulled, the back, comes under tensile stress, while the belly is compressed. In natural materials, such as the wood in a self-bow, the amount of tension they can absorb before breaking can be limited. This means that to accommodate a longer draw, the bow itself needs to be longer too, with the draw weight depending largely on the thickness of the stave and the properties of the wood in use. It will eventually reach the point when the bow can bend no further or simply break.

With their ingenious construction and design, these limitations do not apply to composite bows. Generally, the belly consists of a layer of horn which has excellent pressure-resistant qualities, and the back is covered with one or more layers of sinew, which handles tensile strain very well. The back and belly are glued to a wooden core, which lends stability and defines the shape of the bow. Rather than being straight, composite bows are usually recurved, their reflex tips pointing away from the archer in an unstrung state. While drying, the sinew on the back contracts, sometimes up to a point where the tips touch or even overlap, making the unstrung bow a pre-loaded spring, so it will take strength and proper technique to even brace it.

Slow-drying fish glue was used to stick the different components together, meaning the drying could take more than a year to complete. This meant that making composite bows was expensive and time-consuming. They could also be very delicate and needed to be warmed up before bracing. They could develop twists in the limbs which needed to be corrected before shooting and were best stored in a temperate environment.

The combination of elastic materials, and the recurve shape, allowed for composite bows to be built shorter than self-bows, but to still deliver the same, or even more power to the arrow. In its strung state, a recurve bow is already under a lot of tension, so it is more difficult to draw initially than a straight bow. When drawn, only small portions of the limbs bend, while the limb tips act as levers, reducing the amount of strength it takes to pull the string further back.

This means that at the beginning of the draw, the archer must overcome the resistance caused by the effectively shorter string, but as soon as it lifts off the curved ends (bridges), the draw weight feels considerably reduced, which is known as let-off – the same principle achieved with eccentric pulley wheels in modern compound bows.

To protect them from moisture, composite bows were usually covered with bark, rawhide, or leather, which could be lacquered and were often beautifully decorated. That they do not work in wet or cold climates is a myth, easily dispelled by the fact that such bows have been successfully used throughout Asia and Europe in all weather conditions.

Although many modern composite bows use materials such as aluminium, glass and carbon fibre, fast-drying synthetic glues, and have features such as pistol grips and arrow shelves, the modern laminated recurve bow is essentially still an evolution of the historic composite bow and makes use of the same mechanical principles.

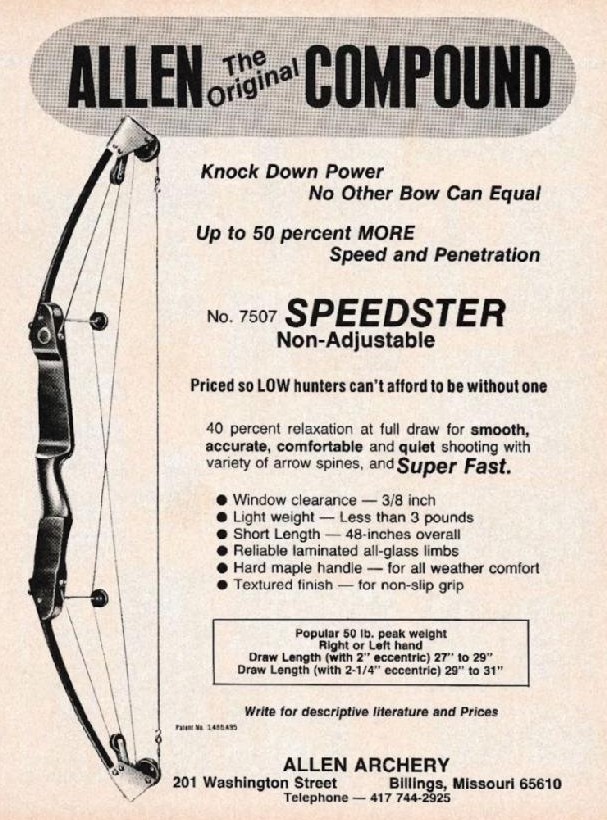

The Compound bow

The Compound bow is a complex modern bow that uses a lever system of cables and pulleys to bend the limbs. This bow was invented by the American – Holless Wilbur Allen Jr. in the 1960s. He basically sawed the ends off a conventional recurve bow and then added pulleys (cams) to the end of each limb. One or both cams have one or more cables attached to the opposite limb. When the string is drawn back the cams turn and flex the limbs of the bow building energy potential.

The cams are eccentric, so they act as levers and allow for the archer to hold the bowstring at maximum draw without using too much strength. This is known as let off (see composite bows above) and allows for more accurate and far less strenuous aiming.

Compound bows still have a riser, and this holds limbs, sights, stabilizers, and quivers. It is usually made of aluminium, a magnesium alloy, or carbon fibre to be as rigid as possible. Composite materials are used for limbs because they must be flexible yet not break under the stored energy which is used to shoot the arrow which can reach speeds of up to 113m/s. Bow strings and cables are made from high-modulus polyethylene, and are used and designed to have great tensile strength and minimal expansibility to transfer all of its energy to the arrow with minimal loss.

The advantages of a compound bow are that it stores more energy potential and can shoot faster than other bows of the same size. They have been designed with horizontal limbs which lessens the recoil and vibration making the bow more accurate, they also use a sighting system that consists of a back sight and a front sight, which helps with aiming.

The compound bow also has some disadvantages. It is a fairly complex design with a large number of moving parts. They require more maintenance than other types of bows and create more points of failure, and they can be damaged when fired without an arrow. Replacing bow strings or cables requires a special tool (bow press) that can sometimes be found only in archery pro shops. Also, because the bow is so light it is easier for the archer to twist the bow and make left-right errors.

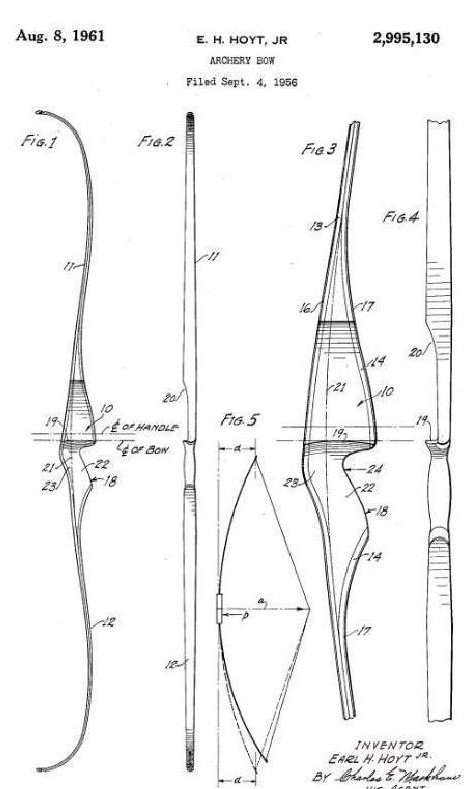

The Recurve Bow

The bows used in early archery competitions were not that different from the self-bows that had been so prevalent throughout history. That changed in the 1950’s with the advent of fibreglass bows and in particular Earl Hoyts’ “Push Handle” design, a design more in line with the shape of the archer’s hand. This “pusher” allowed for a more stable platform, which proved helpful for improved accuracy.

To further improve accuracy, he also included a bow or sight window (although the inventor of this improvement is still disputed), but as you can see from the image in Figure 7, the modern recurve bow was born.

In the 1960’s the idea of the three-part, or takedown bow such as the Black Swan Archery bow began to take shape. This allowed for easier transport of an archer’s gear and advances in the lamination process meant that more exotic shapes could be formed.

As time moved on, the modern lightweight metal risers and accessories such as sights, clickers, weights, and stabilisers became available, and the humble bow became the modern recurve bow as we know it.

However, there are still modern archers who choose to shoot as close to that original design as they can, and this has created the “barebow” category of recurve bows. Barebow archery has seen a significant rise in popularity in recent years. While some accessories are permitted such as close-fitting weights and buttons, accessories such as long rods, sights and clickers are all prohibited and even the weights have to be able to pass through a standardised ring to be allowed to be fitted to a barebow for competition use. This has led some of the major manufacturers to look into designing specialist barebow risers such as the Mybo Mykan or the Gilo GT.

Conclusion

Whatever type of bow you choose to shoot you are welcome at the club. We have a number of coaches who have been trained to support both able-bodied and archers with more complex needs including those who may have a physical disability. Both recurve and compound bows can be fitted with adaptions to enable archers to enjoy the sport regardless of their disabilities, you only have to look at the recent successes from the GB Paralympic team to see that there are options for all in modern archery.

We look forward to seeing you at the club.

Mark Allen November 2024